You have no items in your shopping cart.

Application Story: Spotlight on Australian Manufacturing

Milltech Martin Bright Steel has grown progressively to be Australia’s leading Engineering Bar Processor, producing in excess of 30,000 tonnes per year and specializing in Superquench, Marcrome and Marbrite products.

To meet the challenges of production, they required a robust automation system capable of motion control, temperature monitoring and process control with PID loops, timer and high-speed counter control. Using the P2000 and other AutomationDirect equipment, they were able to achieve a fully automated system with a short set-up time using recipes. Here is a brief summary…

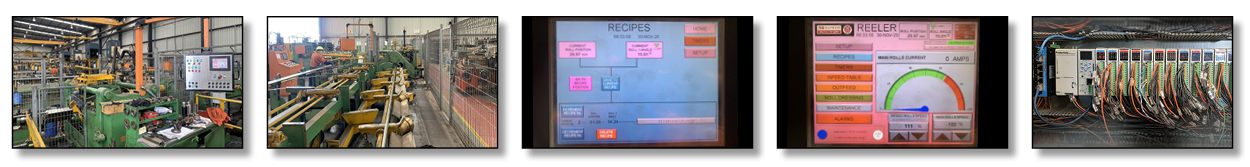

INDUCTION HARDENER - P2000 PLC

The Induction Hardener heats round steel bars with an induction coil (typically about 700 deg C) and quenches with water. The induction coil is positioned by two (vertical & horizontal) motors and two 4-20mA linear transducers connected to a P2-08AD-1 analog input module. Their positions for each bar size are saved in the PLC as a recipe for later use via the C-more Operator Interface Panel.

The bar is pushed by the carriage that is driven at a precise constant speed by a VSD and motor with encoder connected to a P2-HSI and the P2000 PID software module in the PLC. This keeps the speed and temperature of the bar constant at the heating coil. The Induction heating is turned on and off at the start and end of the bar using measurements obtained from carriage position and a light curtain.

REELER - P2000 PLC

The Reeler straightens round bars as they pass through two rollers, one concave and the other convex. Linear transducers sense roll positions and roll angle (P2-08AD-1 Analog card). Roll speed is set via P2-04DA and roll current is read via P2-08AD-2.

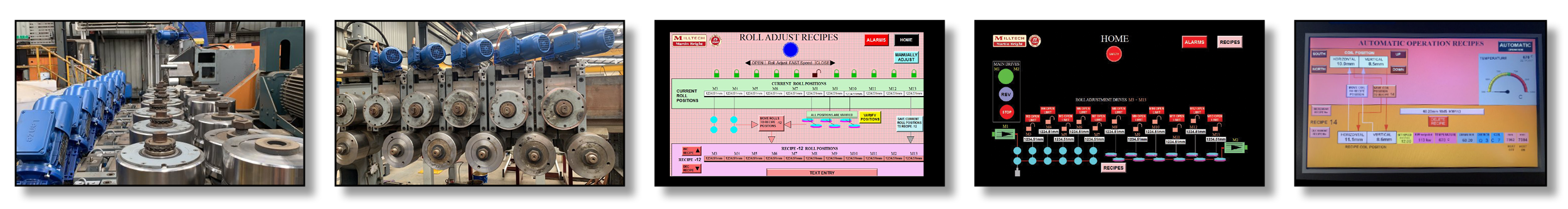

BAR STRAIGHTENER – P2000 PLC

The straightener straightens square or hexagon bars. It has 5 vertical and 6 horizontal pairs of rollers that are adjusted with motors with encoders. Once setup, the positions can be saved to recipes.

All machines are fully automatic and have very short setup time using recipes. Productivity Suite is a free, full-featured software package using instruction block-style configurations. The P2000 PLC is a perfect match for the C-more EA9 series HMI and SCADA products. Up to 16 C-more HMIs can be connected to the P2000 CPU via Ethernet, for flexible control and visibility.

Special thanks to Roland Harding, (Electrical Engineer) of Milltech Martin Bright for article and image contributions.

Milltech Martin Bright is proud to be an Australian manufacturer of high quality engineering bar, supporting local jobs and our economy.

To learn more about Milltech, visit www.milltechmartinbright.com

Learn more about the Productivity family with this introductory video.

Note: Starter kits available in US only. Check current $AUD prices.