You have no items in your shopping cart.

CLICK Software & Programming Cables

PLC hardware is half of the equation with software being the other. PLC software provides the tools to program the hardware for your specific needs. Download CLICK PLC | CLICK PLUS programming software FREE. This software's simple, practical instruction set is easy to use and will get you up and running quickly. Cables are also available.

| Product Code | Product Name | QTY | Price ($AUD) | Action |

|---|

CLICK® Series Programmable Logic Controller Software and CablesThe CLICK PLC programming software can be downloaded for free and provides an intuitive programming tool that will get you up and running quickly. |

|

21 easy to use instructions

- The CLICK PLC supports a very simple but practical instruction set.

- The 21 easy-to-use instructions can cover most applications that are suitable for this class of PLC.

- (The CLICK PLC does not support DirectLOGIC Series PLC instructions.)

8,000 steps program memory

- The CLICK CPU module can store up to 8,000 steps of ladder program in its flash EEPROM memory.

Decimal memory addressing

- The I/O numbering system is decimal to make it easier to count the number of I/O points and data registers.

On-board documentation

- Don't need all that memory for your ladder program? You can opt to store all the documentation (your comments, tag names, etc.) on-board the CLICK CPU as well. This can be especially useful if you find yourself editing the program with a different programming PC in the future.

Math Made Easy

- Spreadsheet style math instruction- just enter a formula (with embedded PLC tags if you wish) and enter a "result tag". Supports all the standard scientific calculator functions. Make it a "one shot" with a simple check box. It really couldn't be any easier.

FREE CLICK Software

The best way to understand the ease of programming for CLICK is to download the Software. Fully functional, you can create a PLC program in minutes. Or use it to configure a system and calculate your power budget automatically. The CLICK Programming Software is designed to be a user-friendly application, and the tools, layout, and software interaction provide ease-of-use and quick learning.

The simple operation of this software allows users to quickly develop a ladder logic program. The extensive help files provide information that will help you get acquainted with the software quickly.

CLICK PLUS

CLICK PLUS PLCs use the same software as the original CLICK PLCs.

The CLICK PLUS PLC programming software provides a very simple but practical instruction set of 25 easy-to-use instructions that can cover most applications suitable for this class of PLC. The software can be downloaded for free from our store; a software CD is available for purchase if needed.

- Simplified programming makes CLICK PLUS PLCs easy to learn and fast to program

- User-friendly programming environment with drag and drop functions, Data View monitoring, subroutines, and interrupts

- Streamlined PID loop control capability (up to 8 loops simultaneously)

- Easy-to-use interface for configuring high-speed I/O

- Velocity Move, Position Move, and Home instructions provide simple motion control

- Wi-Fi settings can be quickly provisioned using Bluetooth

- Enhanced security features including password support, port management, secure email using TLS, and session-based connections

- Simple scaling function for analog signals can easily transform a raw process signal, like 4-20mA, into meaningful engineering units.

EtherNet/IP™ (Adapter Server) Protocols now supported |

|

The CLICK Ethernet PLC models now support the EtherNet/IP as an (Adapter Server) device. This allows the CLICK PLC and its I/O to be controlled by an EtherNet/IP Scanner (Client). Take advantage of the low cost CLICK PLC I/O selection for your application needs with fast and easy configuration to your existing network.

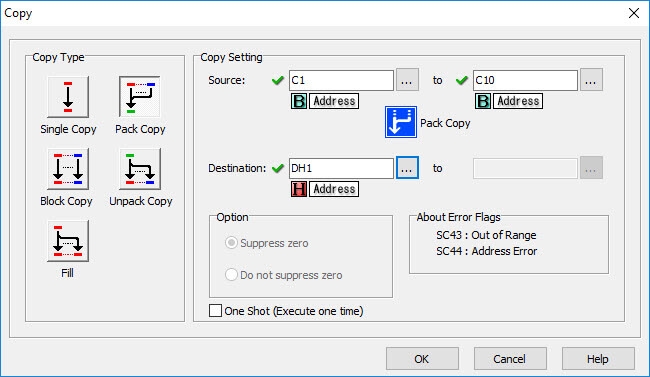

Copy Instructions ImprovementsThe Copy Instruction offers the ability for data manipulation when communicating to other devices. Improvements have been made to this instruction that will increase the ability for users to work with data from both Modbus and EtherNet/IP devices. Improvements include:

|

|

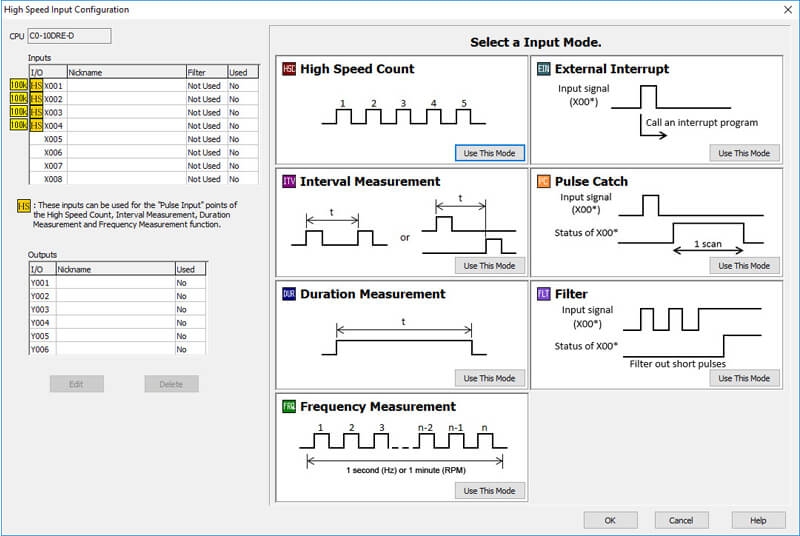

Added Support for High Speed Counting and Timing on Ethernet CPU models with DC Inputs

High-speed input functions including pulse counting and frequency measurements are made simple with the user-friendly graphical user interface (GUI). Simply choose the desired high-speed function and the interface will guide you through the available features and options.

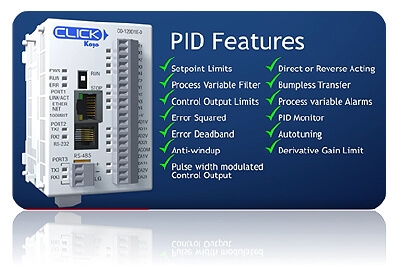

CLICK PIDThe CLICK Ethernet PLC's now supports up to 8 PID control loops executing every 100ms. The simple PID Configuration tool saves you time by doing most of the

PID Loop configuration of a connected CLICK PLC.

|

|