You have no items in your shopping cart.

Productivity1000

The P1-550 PLC is a compact yet highly capable member of our Productivity controller family. Packed with many of the features you love about the Productivity series but housed in a smaller, slimmer design, this PLC is a popular choice for seasoned and beginner engineers alike. It was difficult to narrow it down, but here are just 5 features we love about this reliable, super-compact, full-featured CPU that we think make it such a popular system.

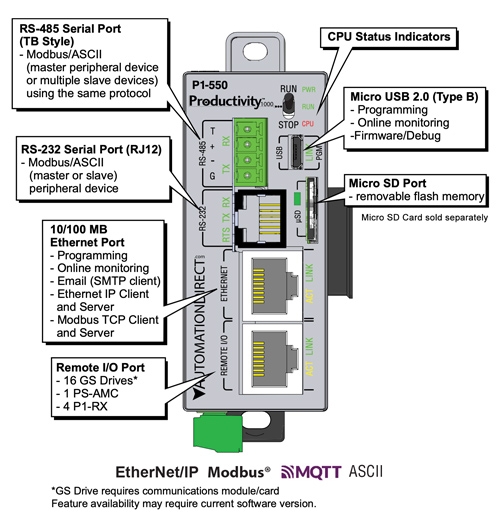

1. Built-in Communication

The Productivity1000 comes with up to 5 built-in communciation ports for easy connectivity to your PC or various industrial networks.

Micro USB: MicroB USB port for easy plug-and-play programming

Serial RS-485: 4-pin serial Modbus RTU/ASCII or custom protocol connection

Serial RS-232: RJ12 serial Modbus RTU/ASCII or custom protocol connection

Ethernet 10/100Mbps General Purpose: RJ45 Ethernet port for PLC programming and/or Modbus TCP, EtherNet/IP, MQTT, custom UDP/TCP connections

Ethernet 10/100Mbps Remote I/O: RJ45 Ethernet port for easy GS series variable frequency drive, PS-AMC motion controller, Protos X field I/O, and P1000 remote I/O (P1-RX) connections (P1-550 ONLY).

Serial Ports

The two serial ports are included on the Productivity1000 CPU support communication to peripheral devices:

(1) RJ12 (6P6C) port for RS-232 devices

(1) 4-wire screw terminal for RS-485 multi-drop devices

These ports provide Modbus RTU Master/Slave capability, ASCII In and Out capability and Custom Protocol over Serial capability. The RS-485 port can support up to 50 multi-drop devices (more if repeater is added to network).

Built-in Ethernet

Both Productivity1000 (P1-540 & P1-550) CPUs come standard with a general purpose Ethernet port and two of the top industrial Ethernet protocols in our market. Modbus TCP and EtherNet/IP are a must for any up-to-date networked control system. MQTT is also supported which is fast becoming an industry requirement as the IIoT and machine-to-cloud connections become more and more prevelant. 10/100Mbps multipurpose Ethernet port for programming, monitoring, firmware upgrades and a mixture of the following client/server connections:

• 16 Modbus TCP Client connections (CPU Master)

• 16 Modbus TCP Server connections (CPU Slave)

• 32 EtherNet/IP Scanners (CPU Master)

• 4 EtherNet/IP Adapters (CPU Slave)

• 4 cloud connections using MQTT

A total of 128 EtherNet/IP connections and over 5000 EtherNet/IP messages per second! And unlike many controllers, the Productivity series CPUs support both Explicit and Implicit (I/O) messaging for greater functionality.

The Productivity1000 also provides a Custom Protocol over Ethernet (CPE) option which gives the user the ability to create their own communications protocol between the Productivity series CPU and a 3rd party Ethernet device via TCP or UDP.

The ProNET feature is also available and allows any P-series CPU to seamlessly share data by publishing to or subscribing to data from other P-series CPUs. Up to 32 publishers and/or subscribers are allowed per CPU.

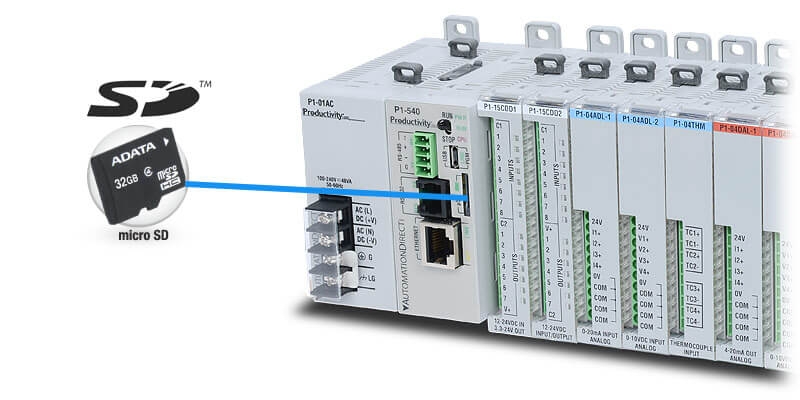

2. Data Logging

The Productivity1000 allows for up to 32GB of historical data to be saved to a removable microSD card (sold separately). Track up to 64 tags at a time and save the data to the removable micro SD card stored in the CPU. Capture up to 32GB of data either periodically (minute, hour, day, week, etc.) or when certain events occur. Scheduling and setup is done with the easy-to-use Data Logger configuration tool in the software. Log tag data, system errors and system events which can be used to track efficiency and performance, troubleshoot recurring or intermittent faults, and predict future breakdowns.

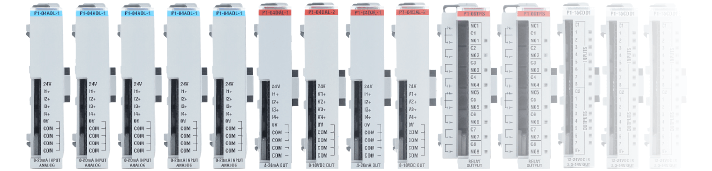

3. Slim Stackable Design

The super slim form factor requires minimal panel space (approximately 8.9" for an 8 module system) and the stackable design allows for simple I/O expansion.

The Productivity1000 requires no base or backplane and can easily be expanded with up to 15 snap-on I/O modules when using the P1-02AC power supply. The P1000 system can support up to 240 discrete I/O points or 120 analog I/O channels total. The I/O modules can be easily added or removed using the single latch mechanism on the topside of each module. This stackable design allows you to purchase only the I/O required for your particular application.

This versatility also means you can use the Productivity1000 CPU as a stand alone, low-cost data logger or protocol converter (no I/O modules).

I/O Expansion Modules

Several expansion I/O modules are available to choose from:

Discrete

Analog

Temperature

Relay

High Speed

PWM

The P1-RX module adds remote I/O capability to the P1-550 CPU, providing up to 512 remote I/O points (4 remote bases with 8 modules each).

4. Productivity Built-in

There are many features integrated into the Productivity1000 series PLCs that provide unmatched ease of use when expanding, configuring and wiring your hardware.

Built-in Accessibility

- The single top-side latch on every I/O module provides free and clear access to the latching mechanism when adding/removing I/O modules.

- The pivoting wire cover on each I/O module displays the wire label in any position so it’s visible at all times.

- A fulcrum lever is designed into every I/O module for easy terminal block removal.

QR codes provide support at your fingertips!

All Productivity1000 I/O modules have QR codes printed on the underside of their wire covers. Scan the code with your smart phone or tablet QR app to get the latest specifications/ wiring diagrams for that module.

5. Multiple Wiring Options

Choose from spring clamp, screw terminal or the popular ZipLink wiring solution for your I/O wiring needs.

Choose from spring clamp, screw terminal or the popular ZipLink wiring solution for your I/O wiring needs.

ZipLink pre-wired cables and modules save valuable time, keep your installation clean and efficient, and use half the space at a fraction of the cost of standard terminal blocks. The ZIPLink wiring solution eliminates the need for hand wiring every I/O point in the control panel. Simply plug one end of a ZIPLink pre-wired cable into a supporting PLC or I/O module and the other end into a ZIPLink connector module and all the connections are made. Connect field wiring to the connector module and the I/O circuits are complete.

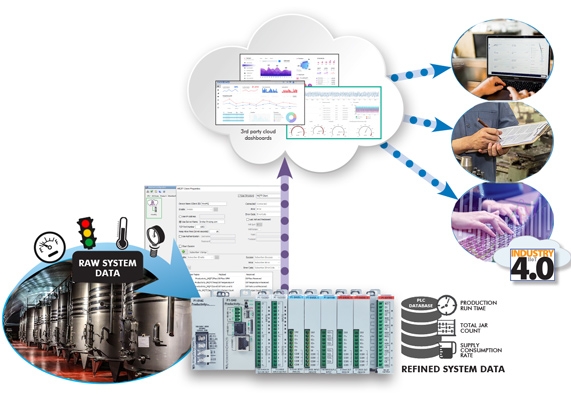

More about Data Logging and Cloud Communications

Industrial machines/systems are more connected than ever before, whether internally with upstream IT management systems or externally with remote support personnel, modern-day plant-floor machines/systems need to communicate to a variety of networks. Cloud networking, with its computing and data storage platforms, has also become a viable solution for analyzing and accessing production data from anywhere at anytime. Using powerful cloud platforms such as Microsoft Azure® or IBM Watson® to analyze production-floor data can provide better process efficiency, improved plant-wide resource management and less operational downtime.

Productivity PLCs have the communication capabilities and processing power needed to not only control plant-floor machines but gather valuable data from them, package it, and send it on to higher level analysis systems.

Mulitple data gathering options

Productivity PLCs offer many I/O options to choose from for your system data collection. I/O modules, available in analog, discrete, high-speed, relay, and temperature versions, allow you to create the custom I/O configurations your application needs. And with Modbus RTU, Modbus TCP and EtherNet/IP protocol support, Productivity1000 PLCs can easily gather raw data from a variety of VFDs, sensors, switches, encoders, pilot devices, or almost any other control component your system may have.

MQTT

The MQTT protocol has become the frontrunner for many machine-to-machine (M2M) and IIoT/cloud networking applications, due to its lightweight overhead and reduced bandwidth consumption. Productivity PLCs support MQTT communication and with fill-in-the-blank MQTT messaging configurations, delivering vital data to advanced cloud computing platforms is easy.

Compatible with MQTT brokers and cloud platforms/services including:

• IBM Watson®

• Mosquitto®

• HiveMQ®

• Thingsboard®

Refining data into something meaningful

The Productivity Suite programming software makes refining raw data into a meaningful metric a cinch. With a multitude of simple-to-use instructions combined with the computing power of a Productivity CPU, Productivity Suite can easily transform a raw process signal, like 4-20mA, into a consumption rate, a production throughput, an energy efficiency score, a rejection percentage, or any other metric that's vital to you.

Want to learn more about the P1-550 PLC or our product range? Give us a call and speak to our sales or technical support staff. 1800 633 040 (Aus) or 0800 633 040 (NZ)

November 2023. Images and article contributions courtesy of AutomationDirect.com

This publication may contain references to products produced and/or offered by other companies. The product and company names may be trademarked and are the sole property of their respective owners. Direct Automation Pty Ltd disclaims any proprietary interest in the marks and names of others. All prices shown are trade prices and are exclusive of GST. Prices are subject to change, orders will be accepted at the pricing ruling at the time of our acceptance of orders. Please refer to our online store for current prices. Images for display purposes only and may be generic.